coating impact test|impact resistance in coating : mfg ASTM D 2794 provides a procedure for rapidly deforming by impact a coating film and its substrate and for evaluating the effect of such a deformation. The organic coatings under test are applied to four or more suitable thin metal panels. Resultado da Nusabet88 adalah situs bet88 terpercaya dan terbaru 2024, daftar sekarang dan mainkan game dengan taruhan minimum yang rendah dan dijamin wd .

{plog:ftitle_list}

WEBAvailable on CBC Gem, Prime Video, Telus TV+, iTunes. Colin From Accounts is centered on Ashley and Gordon, two single-ish, complex humans who are brought .

ASTM D 2794 provides a procedure for rapidly deforming by impact a coating film and its substrate and for evaluating the effect of such a deformation. The organic coatings under test are applied to four or more suitable thin metal panels. Impact testing is a critical evaluation process that determines a material or product’s toughness, resilience, and durability when subjected to sudden forces or shocks. .

When it comes to ensuring the quality and longevity of coatings, impact testing stands as a critical procedure distinct from other tests like adhesion or elasticity assessments. In this .

ASTM D2794 is a standard test method for resistance of organic coatings to the effects of rapid deformation (impact). This test involves applying organic .The Elcometer 1615 Variable Impact Tester is used to evaluate the resistance of a coating to impact by means of a drop weight test. The Impact Tester is a widely used device for the coating and plastic industries. In both industries impact resistance is measured by a falling weight from a.

The Impact Resistance Test is conducted to determine the resistance of a material to impact damage by establishing the amount of energy necessary to cause failure of a coating.

Pacorr offers an excellent testing machine to perform impact obstruction of paints by methods for Direct Paint Impact Tester and Indirect Paint Impact Tester.

There are two kinds of test that are performed to determine the impact resistance of paints: Weight falls on a punch which is set on the coated metal sheet also known as Indirect Paint Impact Test. Weight attached to a punch falls on a .The Impact Test is used to determine the impact resistivity and flexibility of coatings. The dual scale instrument is equipped with a special guidance which assures that the distance between each impact is always according to the standard. For correct positioning a spirit-level is built-in. Each Impact test comes as a complete set

Impact tests of different frequencies can be applied to simulate the cyclic fatigue load of the tool under different working conditions as well as different impact frequencies. The main objective of the present article is to review different impact test methods for hard tool coatings. In this regard, impact tests are divided into three categories, including high .This test provides a systematic means for screening coating materials by examining the energy required to rupture the coating applied to a pipe under specified condition of impact from a falling weight. The coating examination is done visually for signs of failure such as cracking or flaking, or instrumentally with a holiday detector.TESTING OF POWDER COATINGS BY CHUCK DANICK McWhorter Technologies. PRESENTED AT: Getting Started in Powder Coating June 15-16, 2000 . • Adhesion (cross-cut test) ISO 2409; ASTM D3002 • Impact resistance ISO 6272; ASTM D2794 • Cylindrical mandrel ISO 1519; ASTM D1737; bend test DIN 53152; NFT 30040The coating impact test, in combination with its finite elements method Ž FEM . simulation w 6 ᎐ 9 x , is suc- cessfully used to characterise thin hard coatings fatigue performance.

what is impact testing

The new “coating impact test” permits variation of the impact force, the impact frequency and the number of impacts for a cemented carbide insert contacting a thin film on a substrate. The resulting behaviour of different composites is presented in graphs plotting impact force vs. number of impacts and allowing quantification of the number .

types of impact testing

The TQC Impact Test is used to determine the impact resistivity and flexibility of coatings. The dual scale instrument is equipped with special guidance whic.Tests to Characterize Coating Powders The table below lists the main tests that are performed on coating powders. The reactivity of a thermoset coating powder is evaluated by gel time and inclined plate flow.; How well the coating powder stands up under storage conditions can be inferred using a simple test called blocking or sintering.Blocking is usually is a challenge with . A common test to determine the abrasion resistance of a coating is the Taber test. To perform the Taber test, the coating material being evaluated is applied to a solid, flat plate. After the coating has cured, the plate is then loaded into the test machine. Abrasive wheels are placed onto the coating and are moved around on the plate's surface .Impact Resistance Test Impact tests signify toughness, or impact strength, of a coating to absorb energy under mechanical load. The drop impact test (or falling-weight impact test) is a commonly used test method to determine the impact resistance. The test standards used for impact resistance testing include:

DOI: 10.1016/S0257-8972(09)90035-4 Corpus ID: 137019868; A new technique for testing the impact load of thin films: the coating impact test @article{Knotek1992ANT, title={A new technique for testing the impact load of thin films: the coating impact test}, author={Otto Prof Dr Knotek and B. Bosserhoff and A. Schrey and T. Leyendecker and Oliver Lemmer and Stefan .

This suggests that the coating has good impact resistance. We further investigated the impact resistance of the different coatings through falling-ball impact tests (Fig. S3 online). As shown in Fig. 4 a, the coatings with different MKP contents exhibited significant different maximum impact resistance heights (h max) for the glass substrate.ASTM D609 – Practice for Preparation & Testing of Paint, Varnish, Conversion Coatings, and Related Coating Products; Paint Impact Test. Paint Impact test is a highly conventional, well-known test which is used to characterize the quality of the paints, varnishes, and coatings that are applied to different types of coatings, substrates .

5.1 Coatings attached to substrates are subjected to damaging impacts during the manufacture of articles and their use in service. In its use over many years, this test method for impact resistance has been found to be useful in predicting the performance of organic coatings for their ability to resist cracking caused by impacts.

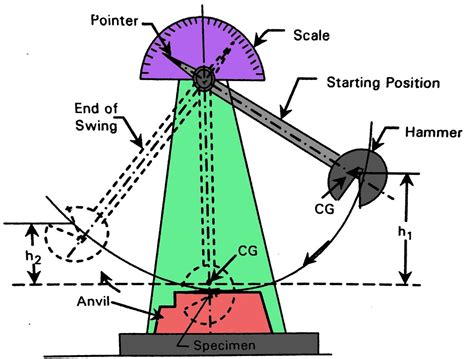

The impact test has been used for several years, among others, for characterizing the fatigue strength, creep, adhesion and residual stresses of coatings at ambient and elevated temperatures under dry or lubricated .Coating Impact Fatigue Test funded by Auto/Steel Partnership through USAMP/DOE. 2. Test Instrument A schematic drawing of the inclined impact-sliding tester used in Phase II of this project is shown in Figure 1. During the inclined impact-sliding fatigue test, a hard ball (the impact body) is mounted on the Impact Test. In the impact test, a coated panel experiences a falling weight or pendulum to test the adhesion under impact conditions. The deformation or removal of the coating at the impact site indicates the .

Any ideas for ways to control impact fusion would be appreciated. Impact fusion is defined as "the tendency of finely divided powders to combine with other particles in the application equipment during the application process." A number of factors can relate to impact fusion problems.NOTE 5—Adequate definition of coating impact strength will result only if the height increment, d, has been properly chosen. When testing polymeric films in the range from 0.254 to 1.016 mm (0.010 to 0.040 in.), . Standard Test Method for Impact .

fabric water vapor permeable tester distributor

"Impact Coatings strives to be a long-term strategic partner to customers within PVD coating, from early test stage to volume production. Our strategy to achieve profitability builds on standardizing and streamlining production of coating systems, driving sales and high value as a one-stop supplier for customers independent of their development stage.

how to test water vapor permeability distributor

To check the resistance of a coating, you can continue testing by gradually increasing the height until the mass produces cracks on the sample. The Impact Tester comes with a support base, ruled tube and an impact mass equipped with a holding device according to the required standard - (for specific accessories, see table on the datasheet).Film thickness testing; A coating thickness test that accurately measure your coating application over wood, concrete, plastics or composites will let you know whether the powder coating has been applied to the preferred thickness. The thickness of the coating can have a big impact on its efficacy, both during application and over time.

Nano-impact test on PVD coatings is an efficient method for investigating film failure mechanisms. During this test, the coating is subjected to repetitive impacts by a diamond indenter, inducing high local deformations and stresses into the film material, which may lead to .Adhesion is also a measurable result of some hardness tests made by pencil hardness, gravelometer, impact (falling dart, etc.) or mandrel bend. Coating chip-off should be recorded during these tests. Finally, loss of adhesion can be noted during some chemical resistance tests where the coating blisters, bubbles up or even falls off.

Impact Resistance (ASTM D2794) measures the resistance of organic coatings to the effects of rapid deformation (Impact). Impact resistance is measured by placing a coated panel in an universal impact tester. A standard weight is dropped a distance to strike an indenter that deforms the coating and the substrate. TheCoatings is an international, peer-reviewed, open access journal on coatings and surface engineering published monthly online by MDPI.The Korean Tribology Society (KTS) and The Chinese Society of Micro-Nano Technology (CSMNT) are affiliated with Coatings and their members receive discounts on the article processing charges.. Open Access — free for .Product Description: Qualtech Products Industry Universal Duty Impact Tester is a precision engineered Impact Test Equipment and Inverse Impact Tester to instantly determine the Impact Performance of samples, sample surfaces and coatings including coatings applied on metal panels, plastic panels and related sample materials.. The visual examination of samples for .

paint impact resistance test

159 MB. Tamanho. 21.12.2021. Atualizado. 6.41. Versão. Baixar Grátis. +0 Avaliações - Seja o primeiro a avaliar o produto! Descrição. Publisher. Nenhuma descrição no momento. .

coating impact test|impact resistance in coating